Materials Engineering Training – Complete Course Details & Career Guide

Materials Engineering Training Full Details

Here’s a comprehensive overview of a Materials Engineering Training Course, including its objectives, modules, duration, target audience, career outcomes, and more:

🧪 Materials Engineering Training – Full Course Details

🎯 Course Objectives

This training provides participants with a deep understanding of:

- The structure-property relationships of materials

- Selection and processing of engineering materials

- Failure analysis, corrosion, and degradation mechanisms

- Modern advancements like nanomaterials and smart materials

- Quality control and materials testing techniques

📚 Course Modules

Module 1: Introduction to Materials Science

- Classification: Metals, Ceramics, Polymers, Composites

- Atomic structure and bonding

- Crystalline and amorphous structures

Module 2: Mechanical Properties of Materials

- Stress-strain behavior

- Elasticity, plasticity, toughness, and hardness

- Creep and fatigue

Module 3: Thermal, Electrical, and Magnetic Properties

- Conductivity and insulation

- Magnetic and dielectric behavior

- Thermal expansion and heat capacity

Module 4: Corrosion and Degradation

- Types of corrosion

- Environmental effects

- Corrosion prevention methods

Module 5: Materials Testing & Evaluation

- Destructive testing (tensile, impact, hardness)

- Non-destructive testing (ultrasound, radiography, dye penetrant)

- Microstructural analysis (SEM, TEM, XRD)

Module 6: Materials Selection and Design

- Performance-based material selection

- Cost, availability, and sustainability considerations

- Case studies in aerospace, automotive, and biomedical sectors

Module 7: Advanced and Emerging Materials

- Nanomaterials and biomaterials

- Smart materials and metamaterials

- Additive manufacturing (3D printing)

⏳ Duration

- Short course: 2–5 days (introductory level)

- Professional training: 4–8 weeks

- Diploma/Certificate: 3–6 months

- Advanced Diploma/Masterclass: 6–12 months

🎓 Who Should Attend?

- Mechanical, chemical, and civil engineers

- QA/QC and inspection professionals

- Research and development staff

- Manufacturing and production engineers

- University students in engineering or physics

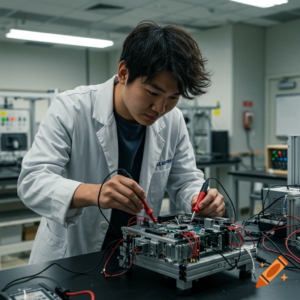

🧰 Training Methods

- Interactive lectures and expert-led workshops

- Lab demonstrations or virtual simulations

- Industrial case studies and problem-solving sessions

- Assessments, quizzes, and final certification exam

🧑🏭 Career Outcomes

Graduates of this training can work as:

- Materials Engineers or Scientists

- Metallurgists

- Failure Analysts

- Corrosion Engineers

- R&D Technologists

- QA/QC Specialists

Industries hiring materials engineers include:

- Aerospace and Automotive

- Oil and Gas

- Biomedical Device Manufacturing

- Electronics and Semiconductors

- Construction and Infrastructure

📜 Certification

Most programs offer:

- Certificate of Completion or Professional Certification

- Some accredited by professional bodies like ASME, TWI, or ASTM

🌍 Training Providers

- Universities with engineering programs

- Technical training centers (e.g., TWI, BINDT)

- Online platforms (Coursera, edX, Udemy, NPTEL)

- Specialized institutes in materials or metallurgy

Here are some effective tags for your Materials Engineering Training content:

Materials Engineering

Engineering Training

Materials Science Course

Metallurgy Training

Mechanical Properties of Materials

Corrosion Engineering

Materials Testing

Advanced Materials

Nanomaterials Course

Engineering Certification

QA/QC Training

Engineering Courses UAE

Industrial Materials Training

Engineering Career Development

Non-Destructive Testing (NDT)

Structural Materials

Smart Materials

Materials Selection and Design

R&D Training

Professional Engineering Development